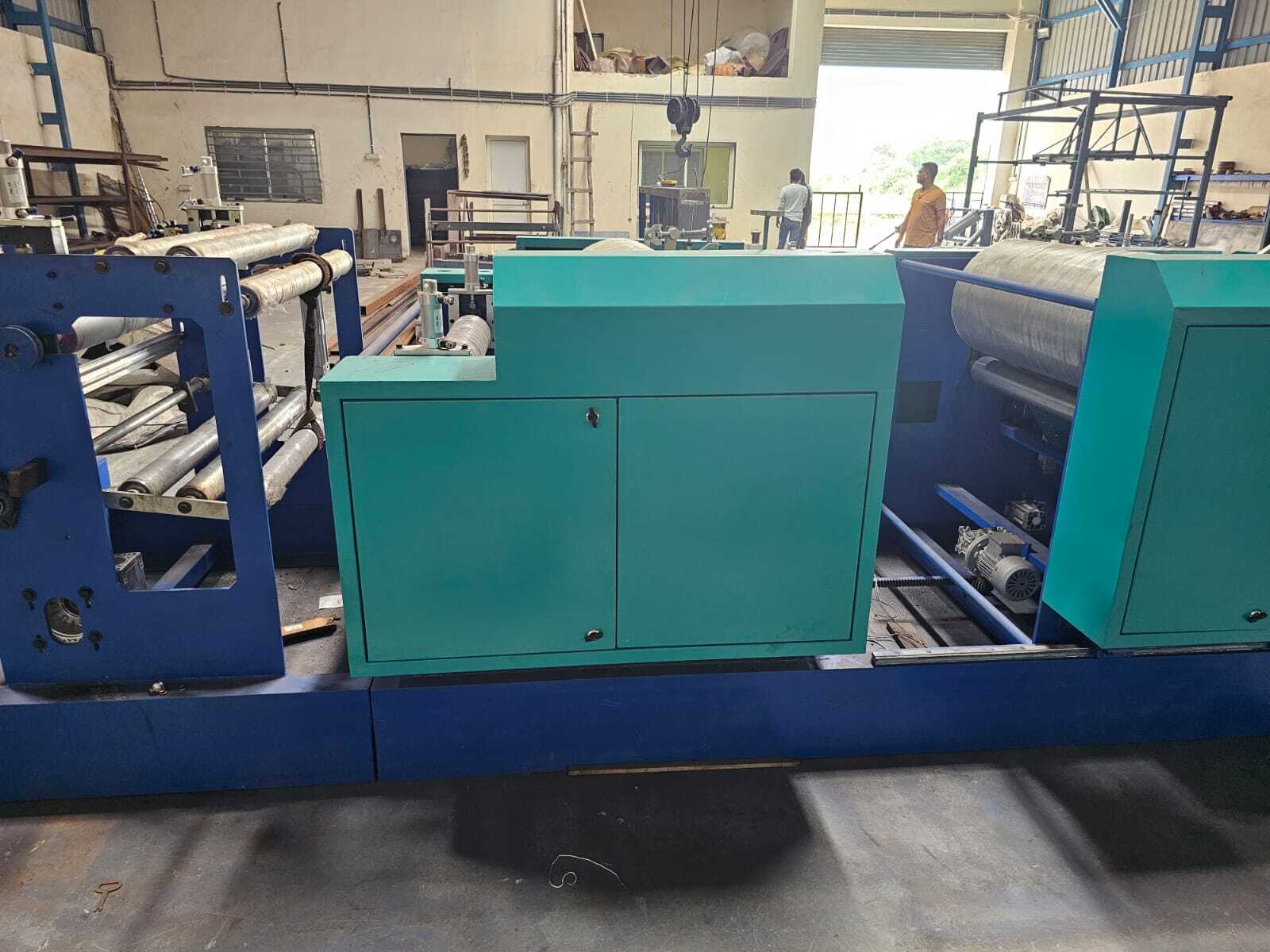

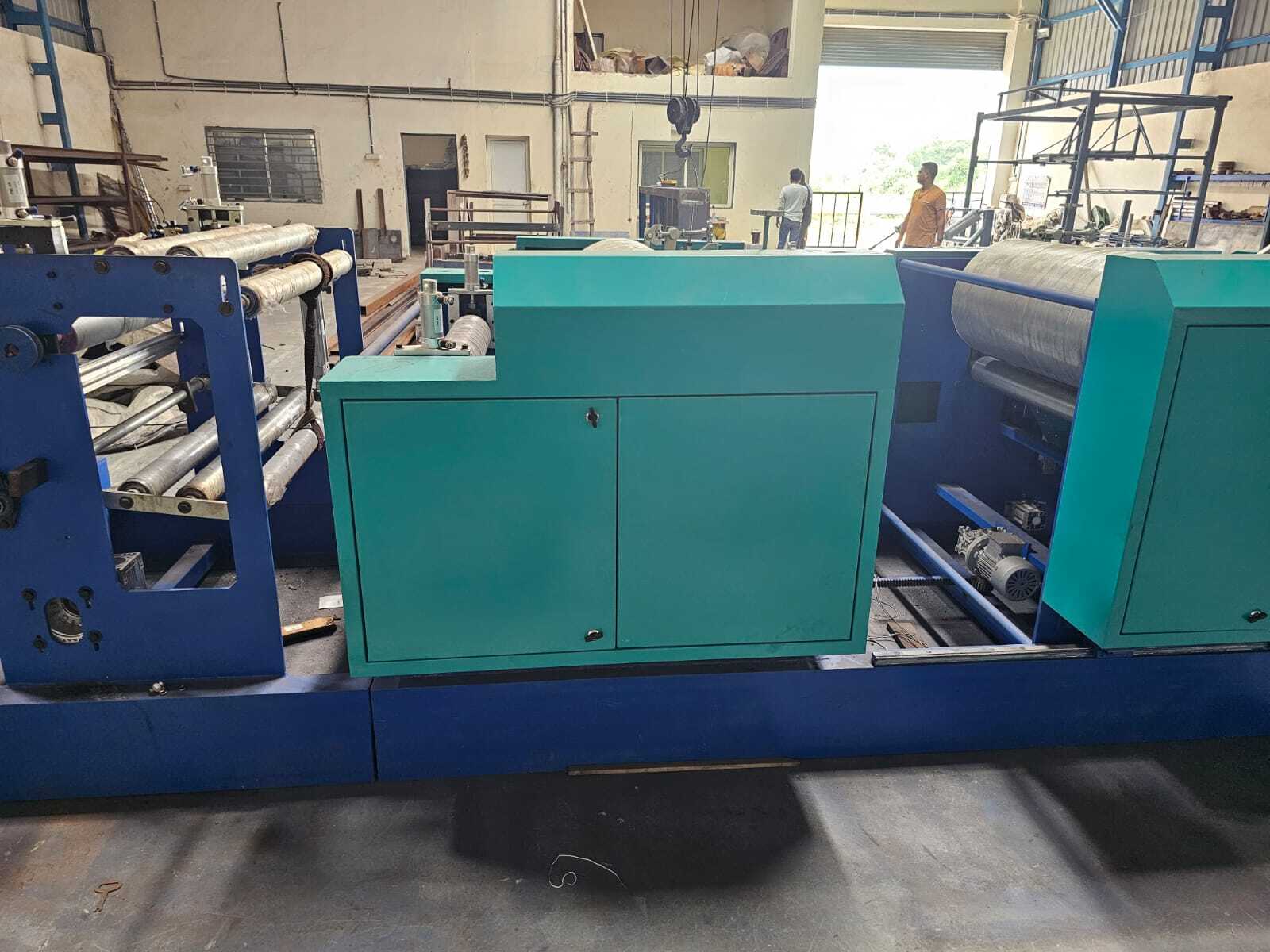

Roll to Roll Printing Machine Without Change Cylinder 8 Color

Product Details:

Roll to Roll Printing Machine Without Change Cylinder 8 Color Price And Quantity

- 1 Set

- 3850000.00 - 4250000.00 INR/Set

- 3850000.00 INR/Set

Product Description

This refers to your requirement of a Eight-color printing machine for printing on PP Woven Bags. We are submitting our lowest quotation with following Specification and terms /Condition.

Roll To Roll Flexographic Printing Machine Without Change Cylinder Model No: HEERHT 8C

TECHNICAL DATA

Fabric Width Max: 36 Inch

Print Width Max: 34 Inch

Printing Possibilities: 6+2,4+4,2+6,4+4,8+0

Repeat Length (Max): As per requirement

Stereo (Photopolymer plate) Thickness:

Minimum 3mm, Maximum 8mm

UN-WINDER (PNEUMATIC LIFTER)

Maximum Reel Diameter: 1500 mm

Inside Core Diameter:102 mm

Maximum Reel Weight:400 kgs

SURFACE REWINDER

Maximum Reel Diameter:1500 mm

Inside Core Diameter:102mm

Maximum Reel Weight:400.kgs

Side Registration Adjustment:Yes

No. of line (per inch) on Anilox roller: 350-400 Line per inch

( Other options available on request)

SUBSTRATES RANGE

Fabric Specification

PP Woven Fabric

The machine can handle, for instance, the above substrates provided they are of good quality. Material web width and thickness should match with the tension range of the machine.

Supply voltage (should be isolated)415 V (-10%), 3 Phase, 50 Hz, earth Neutral

MAX. MECHANICAL SPEEDMax 75 mpm

Note: Actual production speed and quality will however depend on all printing condition such as Type, thickness & quality of the material, Quality of the photopolymer plates, Web width and print repeats, Type of ink and solvents, Operators skill etc.

The manufacturer/Seller reserve the right to change the specifications

FRAME STRUCTURE

Distinctively designed and precisely machined, strong and sturdy,12.mm Iron frame structure which maintains accuracy over long dependable life and ensures less vibration even with optimum line speed. The mechanical construction of each component undergoes extensive tests, ensures optimum performance and overall longer equipment life.

UNWIND SYSTEM

It is mainly composed of

Unwinder, Single station with pneumatic lifter for lifting the PP woven fabric roll (compressor not in our scope).

Shaft (102mm core ID) to hold the reel

PRINTING UNIT

Each Printing unit mainly consists of

2 Nos. Reversible stations,

Minimum cylinder repeat size: 5 mm

Maximum cylinder repeat size: 1180 mm.

1.no. of impression roller dully balanced, grinded and hard chrome plated

1.no. Rubber roller duly balanced

1.no. Anilox roller duly balanced and hard chrome plated

Web aligner attached on the machine frame.

Guide roller at each station is hard chrome plated

Helical gears for smooth functioning of machine

Shaftless winding and re-winding system

INK DRYING SYSTEM

Controlled heavy-duty blower with connecting to deliver fresh air.

Ink drying is obtained by blowing hot air on the web surface through air Blower Unit. The optimized airflow minimizes heat consumption & avoids solvent retention in the printed substrates.

Electric heating based drying system is composed of mainly electric heater, drying chambers with solvent extraction, connecting ducts, exhaust system etc. It recirculates the same hot air and this result in less power consumption

REWIND UNIT

The whole function is controlled and supervised by the controller.

The rewinder unit consists of 1 No. Surface rewind station,

Maximum reel outer diameter is 1270 mm, and maximum reel weight is 500 kgs.

Rewinding shaft supported by bearing on both sides.

Rewind tension control system consists of

1 No. Manual shaft for 102 mm core I.D. is provided.

1 Nos. Gear box by Standard Local is attached with motor on the surface winder

CONTROL SYSTEM HMI & PLC: JINGE BRAND

SPARES: SET OF TOOLS----1.SET

TOTAL POWER LOAD: 50 HP / 30 KW

Weight: 9 Ton appx

Bag Length: 3 Meter

Maximum Roll Size: 800 mm X 1300 mm

Double Side dried on and off Controller by Remote

Machine Dimensions: 58 Ft L X 05 Ft W X 05 H

Other Products in 'Flexographic Printing Machine' category

|

H T ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese